I've been perusing the topics on here and I've seen some pretty good information scattered throughout the posts. I enjoy TIG welding (mainly stainless pipe for sanitary operations, but I digress) and I'm hoping to design an off-set smoker and start welding here at some point when I can find the funds. My question is mainly this: what design features would you guys like to see in your "dream" off-set stick burner?

A couple of items that keep me up at night (not really, but I love welding and food so there's probably some truth to that):

-stainless vs. low-carbon steel

-insulated vs. non-insulated

-wall thickness

-cylindrical vs. square/rectangular cooking zone (does it matter?)

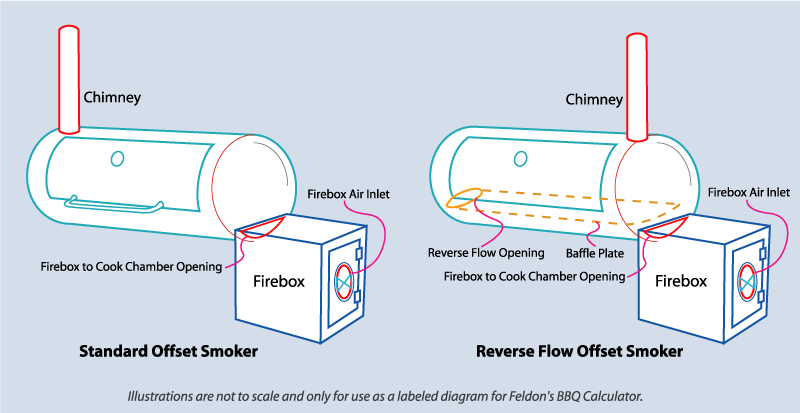

-reverse flow vs. traditional off-set

-tuning plates vs. one single plate (if reverse flow)

-water pan (location, size, etc.)

I actually found a website out there that helps with dimensions of the stack, firebox, etc. but I'm just looking to get information from some experienced cooks. Go crazy with this thing! I appreciate the help and feedback. Maybe I can start moonlighting as smoker fabricator? Thanks guys!

A couple of items that keep me up at night (not really, but I love welding and food so there's probably some truth to that):

-stainless vs. low-carbon steel

-insulated vs. non-insulated

-wall thickness

-cylindrical vs. square/rectangular cooking zone (does it matter?)

-reverse flow vs. traditional off-set

-tuning plates vs. one single plate (if reverse flow)

-water pan (location, size, etc.)

I actually found a website out there that helps with dimensions of the stack, firebox, etc. but I'm just looking to get information from some experienced cooks. Go crazy with this thing! I appreciate the help and feedback. Maybe I can start moonlighting as smoker fabricator? Thanks guys!

Comment