Nice Work!!!

Announcement

Collapse

No announcement yet.

Here's the new 80-gallon pit I'm building

Collapse

X

-

Club Member

- Dec 2015

- 3831

- Northeastern Oklahoma

-

Traeger BBQ124 (in storage)

Yoder YS480

No gas grill anymore

Weber kettle Premium 22"

Blackstone 36" griddle

Camp Chef Smoke Vault 24 propane smoker

Super 55 drum smoker from Smokerbuilder.com

"The Duk" Ugly Duckling self-built 80-gallon insulated firebox backyard offset smoker

"Big Bertha" 320-gallon trailer mounted offset smoker (also self-built)

"The Bronco" 26x48 110-gallon trailer mounted offset smoker (currently for sale!)

Numerous electronic thermometers from Thermapro, Thermoworks and Fireboard.

Personal firearms, home theater, home computing/networking, car audio enthusiast. Smoker building.

About to start the next phase of the build!

What do you think? Saddling in that tank is daunting... as soon as I make the first cut in the horizontal I'm committed. Got a lot of work in that thing to potentially screw it up...

- Likes 4

Comment

-

Club Member

- Dec 2015

- 3831

- Northeastern Oklahoma

-

Traeger BBQ124 (in storage)

Yoder YS480

No gas grill anymore

Weber kettle Premium 22"

Blackstone 36" griddle

Camp Chef Smoke Vault 24 propane smoker

Super 55 drum smoker from Smokerbuilder.com

"The Duk" Ugly Duckling self-built 80-gallon insulated firebox backyard offset smoker

"Big Bertha" 320-gallon trailer mounted offset smoker (also self-built)

"The Bronco" 26x48 110-gallon trailer mounted offset smoker (currently for sale!)

Numerous electronic thermometers from Thermapro, Thermoworks and Fireboard.

Personal firearms, home theater, home computing/networking, car audio enthusiast. Smoker building.

Haven't done much this week - planning on getting to it today. We've had some rain and i needed to get some more materials. Handled that on Friday, picked up a load of steel, but then had commitments for our non-profit group I had to cook for on Friday and Sat morning. So yesterday (Sat) I went out for a few hours and puttered around, getting my steel off the trailer, stacking and organizing, moving things around and getting more room to work and move around the shop.

My buddy got a new toy for his tractor that makes a lot of this a WHOLE lot easier...

This is what I picked up Friday and stacked up yesterday.

3 sheets of 1/4" @ 54x88 (also grabbed another one that went to a friend)

2 sheets of 3/16" @ 48x98, 1 @ 48x66 and 1 @ 48x48.

That oughtta keep me busy for a while, along with the stuff I've got layin' around already.

Also, last weekend, snagged a couple of items for future builds:

These are little, 14" tires on 8" wheels. They'll likely be for another smallish build someday, if I find a 60 or 80 gallon tank I stumble across. The hub pattern looks the same as the golf cart wheels I used, but the studs are much smaller. So I don't think I can use the same hubs - if anyone has any information on where I can find idler hubs for this, I'd appreciate it, or even what I'd call them - small 4-wheeler hubs? I dunno.

Other thing I picked up last weekend:

This is a 30"x64" cylinder, .250 wall thickness, it's actually a 250 gallon tank someone cut the ends off. Got it for a steal, $75. He said he cut the ends to make firepits a couple years ago and now his wife got tired of looking at it sitting there and told him to get rid of it. lol. Oh well, my gain. This will be the firebox for my 500 build, or it could make 2 fireboxes for my pair of 250s. I'm thinking the latter, though, I'd rather use 24" or 26" pipe for the 250s, if I can find some between now and when I need it.

In comparison, this is the pipe I'm going to use for the firebox for this 80 gallon build:

And there you can see the tubing I have waiting for my next cart build, too. That 2x1.5 11g will probably be a cart for a 250g.

So that's where I'm at... today, I think I will start on the firebox. Been waiting a long time to do that. So I'm pretty excited - a little nervous, too, though.

Every time I start a new phase, I get nervous - you know, cutting up plate steel and such, it's expensive stuff, and if I mess up a cut, well, that piece is wasted, unless I can find another use for it later - and you usually can, to some degree. But my firebox will be a 24-30" piece (still debating) of that 18" pipe there, surrounded by 3/16" plate walls in a rectangular box with 2" in between for insulation, 2400ºF-rated ceramic fiber - got this stuff the other day.

So today is a big day - probably cut out my steel walls, cut my pipe down for the center, and maybe start tacking my box up together? I dunno if I'll get that far or not. I have to be extremely meticulous in cutting up my sheets to make sure everything lines up properly and I get a good, square box - Jerod Broussard knows a thing or two about that! Luckily I got to watch/help Aaron (@mrvoigt) do some of this with a big build up at Frank's place in Rolla, so I at least feel a little better about how to go about it.

Wish me luck, hopefully it'll go well! Prolly a lot of measuring and a lot of plasma cutting today! W00T!

- Likes 7

Comment

-

Club Member

- Nov 2021

- 4635

- Alexandria, VA

-

Pit Boss Copperhead 5 vertical pellet smoker

Weber Spirit 3-burner LPG grill w/GrillGrates

SnS Deluxe Kettle

Joule sous vide wand & tub

SnS-500 4-probe w/RF remote monitor (w/extra probes)

Fireboard 2 w/extra probes

Meater+ Wifi/Bluetooth T probe

ThermoPro instant read

Fluke 62Max IR gun thermometer

Full set Mercer knives

WorkSharp Ken Onion sharpener

Weber toolset (tongs, spatula, etc)

Meat Your Maker 11" vac sealer

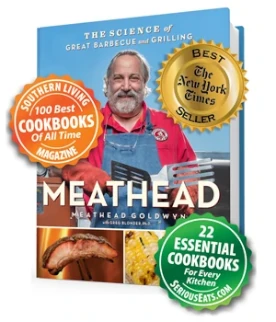

Cookbooks: Meathead; Food Lab (Alt-Lopez); Salt Fat Acid Heat (Nosrat)

...and a partridge in a pear treeeeeeeeeee...

-

Club Member

- Dec 2019

- 2958

- Venice, FL

-

Napoleon Prestige Pro 500

Yoder YS640S

Anova Sous Vide

Avid Armor AVS 7900

Instapot

2 Cuisinart Food Processors

Black Thermapen One

Gray Thermapen Mk4

Red Thermapen Mk4

Thermoworks Smoke

Fireboard

2 Fireboard Pulse wireless probes

Napoleon AccuProbe Thermometer

2 Thermoworks RT8100

2 11” Brisket slicing knives

3 Chef’s knives

1 deli slicer

This is exciting stuff. Serious progress is being made. BTW, I didn’t realize it before now, but every home should have a forklift.

- Likes 1

Comment

-

Club Member

- Dec 2018

- 2136

- Cincinnati Ohio

-

Gear includes: Char-Griller's Grand Champ off set stick burner/smoker, SnS Kamado Deluxe, Weber 22, PBC, Victory gasser, Victory 36 griddle, Smoke Hollow electric smoker. ThermoWorks Thermapen Mk4, Smoke, Signals, and RFX4, Meater+, SNS-500, roti fits 22 n gasser, Emeril countertop TO, InkBird Sous Vide, Potane Vac/Sealer. Fire&Ice griddle/cooler ensemble.

Just got into charcoal Dec ‘21 (PBC)

fav is brisky. Love Turkey on PBC. also Turkey in the glass,(any nice bourbon)

Bud has always been my barley pop.

Been smoking a handful of years, just got serious in the last two or three years. Thanks to AR n @glemn picked up an SnS Kamado for appx 1/3 price of new. I dont think he used it twice. Love AR! keep calm n smoke on! Miss you Bonesy.

-

Club Member

- Dec 2015

- 3831

- Northeastern Oklahoma

-

Traeger BBQ124 (in storage)

Yoder YS480

No gas grill anymore

Weber kettle Premium 22"

Blackstone 36" griddle

Camp Chef Smoke Vault 24 propane smoker

Super 55 drum smoker from Smokerbuilder.com

"The Duk" Ugly Duckling self-built 80-gallon insulated firebox backyard offset smoker

"Big Bertha" 320-gallon trailer mounted offset smoker (also self-built)

"The Bronco" 26x48 110-gallon trailer mounted offset smoker (currently for sale!)

Numerous electronic thermometers from Thermapro, Thermoworks and Fireboard.

Personal firearms, home theater, home computing/networking, car audio enthusiast. Smoker building.

Ok, this weekend's update.

I am sore today. Wobbling around, Mondays always suck anyways, but today I am especially stiff and sore.

Started on the firebox yesterday. Started with cutting some 3/16" sheets - took a LOT of time measuring and trying to make everything as perfectly square as possible. Then cut with the plasma cutter. Did ok, still came out a little off on 2 sides - trying to get used to where to mark my standoff/straightedge for the plasma, etc. So I clamped the two end pieces together and used some flap disc action to get them pretty identical.

Took the ends and a scrap piece to my buddy with a plasma table to cut my door circles and firebox throat opening.

Then I used my dinky Chinese plasma cutter to cut through the big 1" handle and huge thick welds hold it to my pipe I am using for inner firebox. It was painful and slow, but it got the job done. I can't use the cutting torch to save my life, so I didn't even bother trying with that.

Then cut the pipe in half - 30" each. I thought this was .250 wall thickness, turns out it is actually about .330-.340. Used the grinder to cut that. A little tedious, but not too difficult.

Got 'er done, then set the pipe on top of the faceplate, got things lined up as closely as I could and tacked it on all around - I think it came out pretty good! Just a whiskers of gap on an inside corner to weld!

And how's this for an inside corner to weld up and seal? This is the throat opening into the cook chamber.

Here's the pic of where I ended up at the end of the day:

Maybe that will help visualizing what I have left to do. Just the welding and then wrap that pipe in insulation and put the 4 sides on.

I have one of those sides already cut out, 22 x 22 x 30. Need to cut three more, make sure they're absolutely perfectly square. Then I can mount the whole thing to the cart, move the rear axle off the cart and up under the firebox. I'm hoping this thing isn't going to end up too heavy at the end of it all. I calculated the firebox to weigh about 310 lbs back when I thought it was .250 wall pipe, so probably more like 350 lbs actual.

I also didn't show the door - I'm actually doing an insulated door, about 1.25" thick - cut the 18" circle out of the outer box face, that'll be the outer door, it'll butt up to the inner face of the pipe in that picture up there. The inner face is 17.4", allowed for .050 clearance with the internal pipe, but the pipe is thicker than I thought, so I'll end up grinding that down another .150-.160" or so? Not sure. It'll be a grind and fit project, I guess. I'll use a piece of 1.25" x 1/8" flat stock which I'll roll into a circle with my handy-dandy new rolling machine on its way this week. That'll be the spacing in my door sammich. It'll make sense once you see it. lol

So tonight I get to weld! W00T! I am not sure if I'll weld my one lengthwise panel on the bottom tonight, or wait until I get the other 3 sides cut and do them all at once. We'll see how I feel.

I was a long, dirty, heavy lifting day, but got a lot accomplished and feel pretty good about where it's going now.

- Likes 6

Comment

-

Great fit up. What about the Oxy-Acetylene that ain't jiving?

Those yellow fold up saw horses in the background, I have some blue ones, I HATE em. One is currently holding a bicycle light to illuminate the smoke chamber on the big vertical.

- 1 like

-

Yeah, they're not my first choice - but they're what I have. Not my shop, so I'm limited. I'd LOVE to put a welding table in there, a BIG one. I'd really love that, with an overhead gantry or jib crane to manipulate things.

But again... not my shop. So I make do as best I can.

-

Club Member

- Dec 2015

- 3831

- Northeastern Oklahoma

-

Traeger BBQ124 (in storage)

Yoder YS480

No gas grill anymore

Weber kettle Premium 22"

Blackstone 36" griddle

Camp Chef Smoke Vault 24 propane smoker

Super 55 drum smoker from Smokerbuilder.com

"The Duk" Ugly Duckling self-built 80-gallon insulated firebox backyard offset smoker

"Big Bertha" 320-gallon trailer mounted offset smoker (also self-built)

"The Bronco" 26x48 110-gallon trailer mounted offset smoker (currently for sale!)

Numerous electronic thermometers from Thermapro, Thermoworks and Fireboard.

Personal firearms, home theater, home computing/networking, car audio enthusiast. Smoker building.

Welding work last night. Wasn't feeling too well, one of my partners' husband died suddenly yesterday, so I was a bit distracted and upset.

My welds suck most of the time - these are just a few of the ones that sucked slightly less. The rest... well, let's just say it's a good thing they're going to be hidden inside the firebox...

This one was actually welded uphill and came out pretty decent:

So those were the ones I'm not overly embarrassed to show.

- Likes 6

Comment

-

Club Member

- Dec 2018

- 2136

- Cincinnati Ohio

-

Gear includes: Char-Griller's Grand Champ off set stick burner/smoker, SnS Kamado Deluxe, Weber 22, PBC, Victory gasser, Victory 36 griddle, Smoke Hollow electric smoker. ThermoWorks Thermapen Mk4, Smoke, Signals, and RFX4, Meater+, SNS-500, roti fits 22 n gasser, Emeril countertop TO, InkBird Sous Vide, Potane Vac/Sealer. Fire&Ice griddle/cooler ensemble.

Just got into charcoal Dec ‘21 (PBC)

fav is brisky. Love Turkey on PBC. also Turkey in the glass,(any nice bourbon)

Bud has always been my barley pop.

Been smoking a handful of years, just got serious in the last two or three years. Thanks to AR n @glemn picked up an SnS Kamado for appx 1/3 price of new. I dont think he used it twice. Love AR! keep calm n smoke on! Miss you Bonesy.

Caint get no betta, less you doit n get betta! Lookin mighty fine fr my smokin' space. Carry on fine gentleman.

Comment

-

Club Member

- Dec 2015

- 3831

- Northeastern Oklahoma

-

Traeger BBQ124 (in storage)

Yoder YS480

No gas grill anymore

Weber kettle Premium 22"

Blackstone 36" griddle

Camp Chef Smoke Vault 24 propane smoker

Super 55 drum smoker from Smokerbuilder.com

"The Duk" Ugly Duckling self-built 80-gallon insulated firebox backyard offset smoker

"Big Bertha" 320-gallon trailer mounted offset smoker (also self-built)

"The Bronco" 26x48 110-gallon trailer mounted offset smoker (currently for sale!)

Numerous electronic thermometers from Thermapro, Thermoworks and Fireboard.

Personal firearms, home theater, home computing/networking, car audio enthusiast. Smoker building.

Last night I went out and did some more plate cutting. It's been a rough week, friend passed away suddenly, then another friend last night fell and broke his RECENTLY REPLACED hip. <sigh>

Anyways, I was having a lot of trouble getting good cuts with my plasma - turned out I had a bad electrode, so I replaced that, but was being a cheapo and tried to reuse the same tip with the new electrode - apparently this is a bad idea as well. Replace the electrode AND the tip at the same time, or you're going to get crappy looking cuts. <sigh> Kept the ceramic cup and the swirl ring inside, but with new tip and new electrode, it ran much better. It was acting like it did a few weeks ago when I had crappy grounding, so I was trying to troubleshoot that for half the night and it still never worked. But after changing consumables, it was ok.

Still, it's very very tedious. My plasma isn't as great as some of the ones I've seen/used elsewhere. I don't think it's super powerful, not like my friend's Hypertherm 85 which is a frigging BEAST. I would love to get something like that. Cuts steel like butter.

For me, I have to use my cheapie folding metal sawhorses you can see here:

They will do in a pinch, but they're not too stable, and I'm having to shift things around constantly, while repositioning them underneath whatever I'm working on, rechecking the legs to make sure they're still stable (they shift every time I move an object) and these are some heavy things, so it's dangerous as **** to not be 100% stable... anyways. It makes things a LOT slower.

And the steel isn't 100% square, so I have to measure 5 times, mark, remeasure, then trim off an edge to get a square corner, then measure my pieces, reposition the steel so it's facing the right way, with my cut line in between my sawhorses, not running ACROSS them, or that would be bad... then rotate the sheet, recheck and reposition all my sawhorse legs (they moved again!), remeasure 5 times, mark my cuts, recheck all my stability, recheck my measurements, then make ONE cut and repeat the process all over again.

And all this with the problems with my damned electrodes and tips like last night in the middle of it all.

So.... I got 3 pieces cut last night, 22x30", took me about... 3.5 hours or so. Then clean everything up, sweep, put all the tools away, pull the tractor back inside, etc. It's a process.

God I wish I had a shop. And my own tools and tractor. lol

But I'm grateful to have the access I do! Don't get me wrong! I'm super grateful to my friend for being so understanding and patient with me and donating space to me. Just seems like... ugh, took me from 5-9PM to get 3 pieces of steel cut, altogether with all the ancillary crap.

I'm worried when I go back out tonight and look at what I did last night, I'm going to be so disgusted with some of my cuts that I may scrap those pieces and decide to cut others. These are going to be the outside corners of my firebox, so THESE pieces are going to be VERY visible and I want this to be, if not a showpiece (funny, right? lol), at least something I can be proud of, and not something that looks like a cat turd that's been rained on and left out in the sun. <sigh> I'm really thinking at least one of those pieces from last night, if not two, might look bad enough that I feel I can't use them. We'll see tonight, maybe I'm worrying too much.

But it's better to take another night to recut some than to push ahead with something that looks BAD just because I don't want to redo it. I need to get that into my head... the end product is worth more than my time.

- Likes 5

Comment

-

Club Member

- Dec 2015

- 3831

- Northeastern Oklahoma

-

Traeger BBQ124 (in storage)

Yoder YS480

No gas grill anymore

Weber kettle Premium 22"

Blackstone 36" griddle

Camp Chef Smoke Vault 24 propane smoker

Super 55 drum smoker from Smokerbuilder.com

"The Duk" Ugly Duckling self-built 80-gallon insulated firebox backyard offset smoker

"Big Bertha" 320-gallon trailer mounted offset smoker (also self-built)

"The Bronco" 26x48 110-gallon trailer mounted offset smoker (currently for sale!)

Numerous electronic thermometers from Thermapro, Thermoworks and Fireboard.

Personal firearms, home theater, home computing/networking, car audio enthusiast. Smoker building.

Adding a warming cabinet vent

#warmingcabinet #firebox

Tonight I cut a hole in my firebox inner pipe, was a bit disconcerting. I needed to put this passthrough for my warming cabinet before I insulate it and put on the sides of the box. I wanted this to have plenty of flow because I want my cabinet to be able to 'warm' or to 'cook" at high temps, like 400ºF, for things like chikkins. So I used some 7" OD pipe, 5/16" wall thickness.

Took me a long time to get it laid out properly, erased a couple of times, measured a dozen times, because I'm predicting where I want to put it, I want the cabinet up close to the main tank, not just in the middle of the 30" firebox. Only comes out an inch or so different, as I am using a 17.5" diameter air tank.

That measurement notation is from the front face and back face of the firebox faceplate that butts up against the cook chamber. Made sure my firebox endplates were level side to side and then found top dead center with a pipe level made for that purpose I got in a package from Hobo Freight.

I was worried about how to cut it - I've been getting crappy looking cuts with my plasma lately, I found out why today. I pulled the standoff off of the torch and have been using it as a drag tip, and while it works, I'm getting pretty ugly cuts, having some trouble, even on 3/16" plate. So tonight I put the standoff back on it and it cut like a champ, burning through the 5/16" firebox pipe like butter! Very happy again - learning my tools' eccentricities little by little as I go.

Just a little cleaning up and fitting on the pipe piece I cut and it fit in great!

Welded it up, and my usually crappy welds didn't look too horrible tonight!

Overall, I'm pretty happy with my little firebox 'snorkel' tonight!

- Likes 8

Comment

-

Club Member

- Dec 2015

- 3831

- Northeastern Oklahoma

-

Traeger BBQ124 (in storage)

Yoder YS480

No gas grill anymore

Weber kettle Premium 22"

Blackstone 36" griddle

Camp Chef Smoke Vault 24 propane smoker

Super 55 drum smoker from Smokerbuilder.com

"The Duk" Ugly Duckling self-built 80-gallon insulated firebox backyard offset smoker

"Big Bertha" 320-gallon trailer mounted offset smoker (also self-built)

"The Bronco" 26x48 110-gallon trailer mounted offset smoker (currently for sale!)

Numerous electronic thermometers from Thermapro, Thermoworks and Fireboard.

Personal firearms, home theater, home computing/networking, car audio enthusiast. Smoker building.

- Likes 5

Comment

-

Club Member

- Dec 2015

- 3831

- Northeastern Oklahoma

-

Traeger BBQ124 (in storage)

Yoder YS480

No gas grill anymore

Weber kettle Premium 22"

Blackstone 36" griddle

Camp Chef Smoke Vault 24 propane smoker

Super 55 drum smoker from Smokerbuilder.com

"The Duk" Ugly Duckling self-built 80-gallon insulated firebox backyard offset smoker

"Big Bertha" 320-gallon trailer mounted offset smoker (also self-built)

"The Bronco" 26x48 110-gallon trailer mounted offset smoker (currently for sale!)

Numerous electronic thermometers from Thermapro, Thermoworks and Fireboard.

Personal firearms, home theater, home computing/networking, car audio enthusiast. Smoker building.

Surprisingly had a good morning laying down some decent welds.

Had a setback when I ran out of wire and BOTH of my 11 pound backup rolls were out of spec - instead of .035", they both mic'd out at .0385-.095 and wjlhile they would feed through my welder and my torch, they wouldn't feed through the electrode tip. (sigh)

I Looked through my miscellaneous supplies and found a 2 pound roll of Blue Demon wire, so I did some more with that. Welded up all the bottom and side seams, only have the top joints left to do and I'm running on fumes for welding gas. Dangit... I have a roll of flux core I could use, but I've never used that and I don't want my most visible finished welds to look janky, so I may wait on those...

The last little bit of gas I have left I think I want to save to attach this thing this weekend if I can get it in place. Can't get any more gas until Monday. Argh!

Test mockup...

Cut the tank opening (pucker moment!) and fitup.

Pretty good sor far but... I think I need to raise it up another inch. I wanted it as low as possible, but the internal grease dam I had cut into the firebox throat is below the bottom margin of the tank, so... need one more inch, I guess. Story of my life..

I dont know that I'll get it welded on tonight. Dangit. It's 6PM... about 2.5 more hours of daylight. But the final touches to get the opening right may take a lot of finagling, so we'll see. And then see if I have enough gas left to get it securely attached.

Stay tuned!!!

- Likes 5

Comment

Announcement

Collapse

No announcement yet.

Comment