Shrouding the need to fiddle in the cloak of the pursuit of perfection, I stuck pipes on my PBC. As HC said, it’s steampunked! I did think it would look rather cool to use copper, and old Brasserie type effect:

I want to emphasize that this is a totally frivolous exercise in many ways. The PBC works spectacularly. This is just a ‘because it’s there’ type operation.

I mounted the vents far lower than they otherwise would be (usually they are at the top of any smoker, for the obvious reason that hot air rises). I did this because I wanted to impact the ‘static’ air of the PBC as little as possible, while hopefully getting more control over the burn.

Expanding on those points:

The additional radiant heat from the higher aiflow of the coals should raise the chamber temp, hopefully with minimal addition air movement within the drum.

Defining the measure for control:

Typically the PBC gets very hot at the start (380F), then falls back to an operating temp of 275 to 300, stays there for a while (potentially several hours), then falls back again, quite dramatically. A quick stoke of the coals and cracking the lid raise the temp back up (perhaps repeating the initial step of 380 then 275). But sometimes it drops back further and / or more quickly, requiring a repeat of the lid cracking exercise.

I will point out that the finished product in the above scenario always seems to be great. So why worry or change anything? Because sometimes you want a bit more predictability.

So the measure of success is: Can the vents keep the temp at the optimal operating temp with limited trimming.

This allows some ability to compensate for a) Lots of meat in the PBC and more thermal energy is needed and b) later in the cook (after the first 2 - 3 hours) when some fiddling with the coals is required to keep in the optimum zone, c) jacking the heat up for final extra crisping of poultry skin, without cracking the lid or yoyoing the temp.

The build:

Pretty staightforward. Just drilled holes and added parts. There is one internal piece (45 degree elbow) that I’m using to bring the vent hole out over the fire basket. It’s detachable (just slides on) so the basket can be pulled in and out.

Then the sequence of parts from inside to out - ¾ nipple, washer, PBC, washer, cuff (female to female) ¾ elbow, male ¾ to 1â€Â, 20†of 1†pipe, cap (drilled out to ¾).

Stack length: I looked for a ratio / hueristic for stack length to width or draw, and all I could find was “the longer the better, unless its too long, then its worseâ€Â. I presume that the exhaust cooling excessively is the issue, so 20†of copper pipe is probably not the best. To compensate, I used 1†pipe.

To limit the flow out of the stacks, I simply put corks in them. I cut a cork at an angle, so it can cut off half of the exhaust or more.

Testing:

3 parts:

Q2 & Q3: I had 4 basic tests: Half open and full open. Short stack (10 inches) or long stack, pictured. There is also a temporal component - how it acts through time. E.g. both open will give a different effect in the first hour that then the last.

The Results:

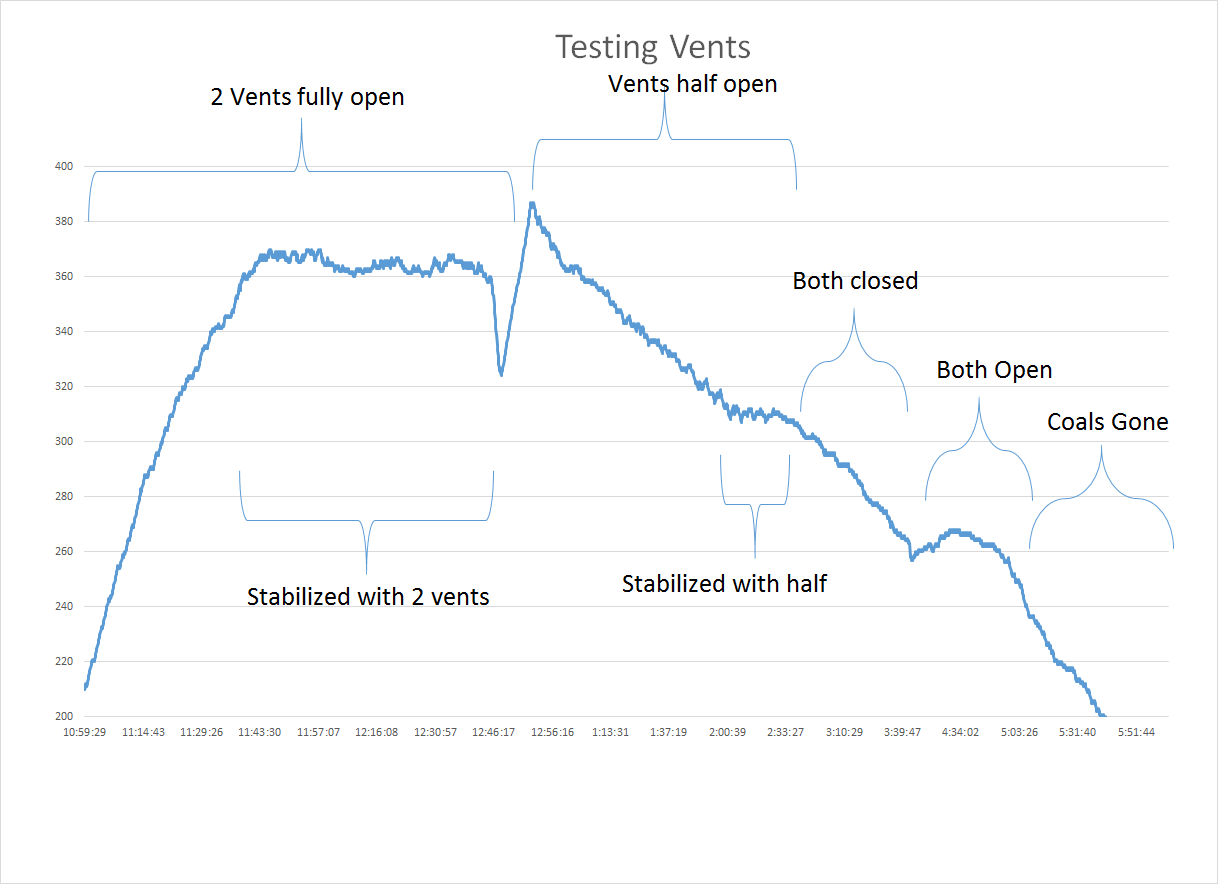

I’ve got graphs, but with all the different combinations they are noisy. Suffice to say, I’ve determined that the pictured set up seems to work. Here’s a graph, but note that the x axis is not scaled correctly (something about the igrill2 output format means excel is not recognizing it as time)

The graph shows about 6 hours, with only one lid opening (the big zigzag). No meat. You can see at the end, the coals were done. You can also see that at the beginning, I just let the PBC heat up with both vents open, just to see where it would settle. Normally, it would got to 380 - 400 and fall back. In this case it climbed to 360 and sat there.

When I cut the flow to half, it trailed off back to just over 310 or so, and seemed to stabilize there. This was the fourth hour of the cook. I then shut them both as a precursor to testing if the pipes could revive the fire. It took an hour to fall back to 260. I then opened both, it staged a 40 minute rally but was then about done. I suspect the long sustained high heat in the first three hours had reduced the duration of the cook.

Chamber temp: Without meat, both open seemed to hold 360F. Which is good, because it indicates that more heat can be generated for the larger cooks, or the temp raised for crisping. Half open, just above 300. I let it run for an hour at both settings just to be sure, but I’m reasonably comfortable that these are the ‘natural’ levels.

With meat (6 racks of ribs, so significant) both open ran at 315 or so. Half open ran between 265 and 275. towards the end of the cook, I opened both vents up and it started to climb back up above 300 and sit there.

Exhaust was interesting to watch. It’s never aggressive with the PBC, however, the pipes were about equal with the upper vents (just eyeballing) hopefully indicating that the chamber airflow was not dissimilar to the original settings.

The ribs: Top notch. Super smoke ring - actually one of the best I’ve had out of it. They were ‘The Pit’ quality. Meat was everything you’d expect it to be.

Stack length. I monitored the exhaust temp in addition to the chamber temp to see the effect of short vs long. Long stacks ran 100F cooler than the chamber temp. Short stacks less than 50 cooler. However, in either case, the chamber temp was about the same indicating (I think) the draw was similar enough to make no difference.

Conclusion:

It worked. I can get higher temps, and have some level of control. However, it’s not responsive. You can see from the diagram that both heating and cooling took time. It will gradually get to its new max temp then stay there, it’s not a quick jump.

However, the max temp is pretty stable, and if the max temp is stable, then temperatures beneath that should be stable too and reachable by trimming.

Judging by the ribs, the cooking chamber is just as moist as it always is. The pronounced smoke ring and the rib succulence was testament to that.

I suspect that Jerod and Spinakers’s setup are far more responsive, and may well have a higher max temp., and when cooking large amounts of meat, probably / definitely better. Whether there is more drying of the meat when small amounts of meat is used will have to be settled at the ‘The Pit First Annual Cookoff’!

But the pipes are pretty, in a steampunk kind of way!

Matt

I want to emphasize that this is a totally frivolous exercise in many ways. The PBC works spectacularly. This is just a ‘because it’s there’ type operation.

I mounted the vents far lower than they otherwise would be (usually they are at the top of any smoker, for the obvious reason that hot air rises). I did this because I wanted to impact the ‘static’ air of the PBC as little as possible, while hopefully getting more control over the burn.

Expanding on those points:

- The PBC doesn’t have a water pan, and has low air flow. The low airflow does two things (IMO): retains a moist air around the meat; allows for a higher cooking temp without drying.

- The PBC is by design a ‘set and forget’ type cooker, and it works really, really well. But I’ve found big variances in the operating temp, which results in fretting over the completion time of the food. I wanted to have the control to be able to push it to its key operating temp (275 - 310) in any situation.

The additional radiant heat from the higher aiflow of the coals should raise the chamber temp, hopefully with minimal addition air movement within the drum.

Defining the measure for control:

Typically the PBC gets very hot at the start (380F), then falls back to an operating temp of 275 to 300, stays there for a while (potentially several hours), then falls back again, quite dramatically. A quick stoke of the coals and cracking the lid raise the temp back up (perhaps repeating the initial step of 380 then 275). But sometimes it drops back further and / or more quickly, requiring a repeat of the lid cracking exercise.

I will point out that the finished product in the above scenario always seems to be great. So why worry or change anything? Because sometimes you want a bit more predictability.

So the measure of success is: Can the vents keep the temp at the optimal operating temp with limited trimming.

This allows some ability to compensate for a) Lots of meat in the PBC and more thermal energy is needed and b) later in the cook (after the first 2 - 3 hours) when some fiddling with the coals is required to keep in the optimum zone, c) jacking the heat up for final extra crisping of poultry skin, without cracking the lid or yoyoing the temp.

The build:

Pretty staightforward. Just drilled holes and added parts. There is one internal piece (45 degree elbow) that I’m using to bring the vent hole out over the fire basket. It’s detachable (just slides on) so the basket can be pulled in and out.

Then the sequence of parts from inside to out - ¾ nipple, washer, PBC, washer, cuff (female to female) ¾ elbow, male ¾ to 1â€Â, 20†of 1†pipe, cap (drilled out to ¾).

Stack length: I looked for a ratio / hueristic for stack length to width or draw, and all I could find was “the longer the better, unless its too long, then its worseâ€Â. I presume that the exhaust cooling excessively is the issue, so 20†of copper pipe is probably not the best. To compensate, I used 1†pipe.

To limit the flow out of the stacks, I simply put corks in them. I cut a cork at an angle, so it can cut off half of the exhaust or more.

Testing:

3 parts:

- Did the air flow the right way?

- How it performs in various set ups, no meat

- How it performs with meat.

Q2 & Q3: I had 4 basic tests: Half open and full open. Short stack (10 inches) or long stack, pictured. There is also a temporal component - how it acts through time. E.g. both open will give a different effect in the first hour that then the last.

The Results:

I’ve got graphs, but with all the different combinations they are noisy. Suffice to say, I’ve determined that the pictured set up seems to work. Here’s a graph, but note that the x axis is not scaled correctly (something about the igrill2 output format means excel is not recognizing it as time)

The graph shows about 6 hours, with only one lid opening (the big zigzag). No meat. You can see at the end, the coals were done. You can also see that at the beginning, I just let the PBC heat up with both vents open, just to see where it would settle. Normally, it would got to 380 - 400 and fall back. In this case it climbed to 360 and sat there.

When I cut the flow to half, it trailed off back to just over 310 or so, and seemed to stabilize there. This was the fourth hour of the cook. I then shut them both as a precursor to testing if the pipes could revive the fire. It took an hour to fall back to 260. I then opened both, it staged a 40 minute rally but was then about done. I suspect the long sustained high heat in the first three hours had reduced the duration of the cook.

Chamber temp: Without meat, both open seemed to hold 360F. Which is good, because it indicates that more heat can be generated for the larger cooks, or the temp raised for crisping. Half open, just above 300. I let it run for an hour at both settings just to be sure, but I’m reasonably comfortable that these are the ‘natural’ levels.

With meat (6 racks of ribs, so significant) both open ran at 315 or so. Half open ran between 265 and 275. towards the end of the cook, I opened both vents up and it started to climb back up above 300 and sit there.

Exhaust was interesting to watch. It’s never aggressive with the PBC, however, the pipes were about equal with the upper vents (just eyeballing) hopefully indicating that the chamber airflow was not dissimilar to the original settings.

The ribs: Top notch. Super smoke ring - actually one of the best I’ve had out of it. They were ‘The Pit’ quality. Meat was everything you’d expect it to be.

Stack length. I monitored the exhaust temp in addition to the chamber temp to see the effect of short vs long. Long stacks ran 100F cooler than the chamber temp. Short stacks less than 50 cooler. However, in either case, the chamber temp was about the same indicating (I think) the draw was similar enough to make no difference.

Conclusion:

It worked. I can get higher temps, and have some level of control. However, it’s not responsive. You can see from the diagram that both heating and cooling took time. It will gradually get to its new max temp then stay there, it’s not a quick jump.

However, the max temp is pretty stable, and if the max temp is stable, then temperatures beneath that should be stable too and reachable by trimming.

Judging by the ribs, the cooking chamber is just as moist as it always is. The pronounced smoke ring and the rib succulence was testament to that.

I suspect that Jerod and Spinakers’s setup are far more responsive, and may well have a higher max temp., and when cooking large amounts of meat, probably / definitely better. Whether there is more drying of the meat when small amounts of meat is used will have to be settled at the ‘The Pit First Annual Cookoff’!

But the pipes are pretty, in a steampunk kind of way!

Matt

Comment